I have made some progress on cleaning up and resetting my workshop spaces, with a focus on balancing out convenience with efficiency.

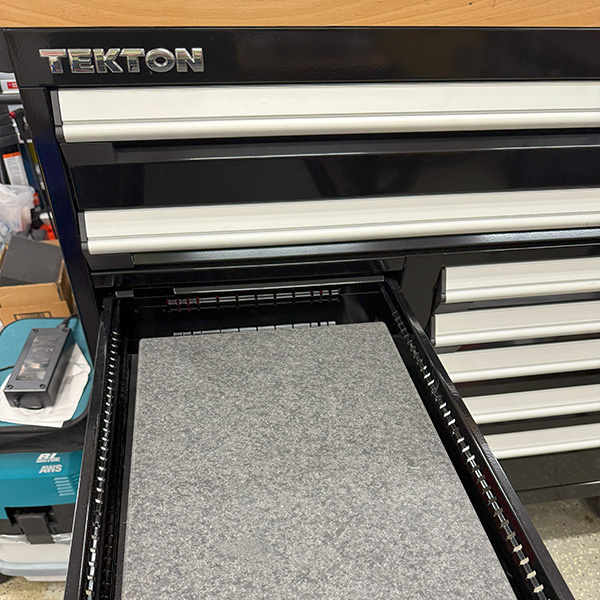

Shown above, I placed my granite surface plate into a tool box drawer, at least temporarily.

I donated my last Gladiator workbench last week, as it was inefficient. It was holding my small benchtop CNC router, which had barely seen much use in recent years, and a tiny super-slow mini CNC mill that’s probably not worth its footprint.

Advertisement

My granite surface plate had to go someplace, and so I emptied one of the Tekton tool cabinet drawers to make room. This is something I would never try with any regular tool box, but the Tekton can hold up to 400 pounds per drawer.

I truly enjoy working on and out of the Tekton tool cabinet, but I think my time with it might be coming to a close. Even at 48″ long, it’s a bear to move around. I think I might be better suited with something smaller.

Read More: Tekton Rolling Tool Cabinets Raise the Bar

At this time, I’m evaluating which equipment is worth keeping in my workspace, and that includes machinery.

For example, do I really need a floor-standing band saw?

Should I replace my benchtop CNC router with a slightly larger floor-standing model? Should I replace my full-size router table with a benchtop model? Where should my miter gauge be stored?

Advertisement

I donated the last of my baltic birch sheets last week, and so of course I now need plywood to make drawers for a tool stand.

I have been planning to move my benchtop milling machine – the one I was supposed to have converted over to CNC already – to an 80/20-based stand with mobile base. Maybe I’ll get that designed and ordered today, and will figure out the need for drawers another time.

I bought maple boards to build a thick woodworking workbench top from, but still haven’t designed the legs. Maybe that will be next week’s design project.

If I replace the Tekton tool cabinet, what will take its place?

There’s been progress, but more is needed. There are choices to be made. I don’t need to keep a parts drawer rack in the garage, but I need a place for parts boxes that are brought up from the basement.

If I upgrade from the old benchtop CNC router to a modern, better, and larger floor-standing model, even if it’s the smaller size I will need someplace for it to go.

I have a squat rack near the fireplace, but always seem injured or too tired to use it, and when I’m not it’s blocked in. Maybe it’s time to take it apart and get a gym membership.

I have $120 in wood boards for a project idea I abandoned 5 years ago. I was supposed to build drawer fronts for my office workbench drawers, but it’s worked well without them. Can I use that wood for projects? Yes. In the near future? Probably not. If it disappeared in an instant, would I immediately rebuy it? No.

I have 3″ x 3″ cherry and maple blanks that I bought at a discount from a woodworking tool supplier 4 years ago. I have immediate projects in mind for those boards. All of them? perhaps not.

At the same time, I’m still filtering through my boxes of overflow, which I dumped into the basement. And new test sample showed up unexpectedly – those will have to go someplace too.

For the longest time, my workspace has been in perpetual “expansion mode” where I add something, subtract a little, and then add more.

While I’m not at a blank slate right now, and am quite far from it, I am at a point where I can make deliberate decisions about what I need or want.

The goal is to avoid dead space. If it’s not frequently used, it can go into the basement, attic, or maybe someplace else. If we’re talking about machinery, then maybe I don’t need that machine, or can move to a portable benchtop model.

My jointer takes up a lot of space, and it’s awesome. I have some longer workpiece projects on deck, but am finding that I am far more interested in smaller projects.

Do I need my cabinet-style table saw? Ideally, yes. Realistically, maybe a benchtop or portable rolling base model would suffice.

I’m donating my MFT because it stays folded up in the corner all but 1 or 2 days every year now.

I have thoroughly explored the differences between a track saw and a table saw. Even though I have a band saw, my table saw excels in rip cuts, and my track saw excels in cutting sheet goods (which I rarely do these days) and large workpieces too large or heavy to move around.

The beauty of a table saw is in its repeatability. It’s simply easier to rip multiple strips or widths with a table saw. For one-cut operations, setup on a table saw or track saw are about the same.

Jessem now makes stock guides that work with portable table saws, which might help with the longer workpiece cuts I always hated to do on smaller machines.

A mobile workbench the size of my SawStop table saw would be a dream.

I could remove the table saw’s extension table and chop off the extra fence rail sections, but that might be a detriment to the next user. The SawStop was never going to be my “forever” table saw, and so I’m hesitant to mutilate it.

I’d like to have a metrology bench, where my granite surface plate and accessories will live. That type of equipment is difficult to hide away. I can work around a smaller table saw, but I already have the smallest size granite plate that would be practical.

Storage and working surfaces are a priority right now, and this will continue to be true, more so than table saw or jointing capacity.

Do I need the ability to plane lumber down to thickness? Can I use hand tools for that? Can I order wood planed close to the desired thickness for a nominal fee?

In theory, I would like to make furniture. In practice, the largest projects on my to-do list are a bed headboard and a workbench with a thick enough top for a flat surface and woodworking vises. Maybe my desired precision bench can also have a 3″ thick laminated top.

One of my projects-in-waiting is a benchtop parts carousel, with a wood base, some kind of post, steel shaft, clamping collars, thrust bearings, and wood trays that spin for small part or tool selection. I don’t need large tools to do this, just more working space and quick access to tools like like my router table.

The shift right now, with my current reset, is in planning out everything as one. Rather than thinking about just the table saw, just a small workbench for precision and measurement tasks, and whether I need an entire shelf for plywood cutoffs that sit collecting dust, I’m planning out the future of the ecosystem.

I also need a shed – I’ve been tripping over my kids’ scooters and bicycle. More space will convince me to stop cleaning up and clearing out, and so I’m putting that off for as long as I can. The scooters can be taken apart and shelved for the winter, and my tamper can go in the basement.

My job is to explore tools, and so I don’t regret that ToolGuyd bought a table saw or jointer that might be too large for my needs. Maybe I’ll have more space 5 years from now or whenever I can eventually decide if I like metalworking or woodworking more.

For what I think is the first time ever, I’m looking at my workshop as if it were an ecosystem, where the focus is not so much on individual tools, storage solutions, or machines, but on how everything fits in together.

Things are moving forward slowly, but I have made progress.

Maybe I’ll have regrets. But if I get into fine furniture making 10 years from now, I can figure things out then.

I do have big plans for lots of projects, and while some of them are going to be large, I need broader tool capabilities rather than bigger. Meaning, if I can fit a workbench, sander, portable table saw, router table, and track saw storage in the same footprint as a cabinet table saw, that might be better suited to my needs.

Space is the most valuable resource. If I can grab a portable table saw, roll it outside or drop it down on the ground (not recommend), portable stand, or folding workbench (also not recommended) and make a cut or two in 5 minutes, that’s more valuable to me than needing at least a half hour to move my cabinet table saw, dust collector, and maybe mobile workbench in order to make the same cuts.

My table saw is blocking my router table which is in front of my band saw, and my 4″ duct dust collector is on the other side of the jointer. A stack of wood boards is in the spot where my band saw used to be stored when it wasn’t used.

I tested out a Jet 6″ helical jointer (not helical style), and while it was very good, I was almost immediately convinced that I should buy a full-sized 8″ jointer to understand the differences. There is a world of difference. I donated the Jet as it was too limiting. I hadn’t written it up yet because I couldn’t recommend it to anyone.

For the projects I want to work on, maybe I might be better served with the Jet and a router sled for larger workpieces. Aside from worktops and a woodworking bench, I won’t really need the length of the beds.

Jointing a workpiece that’s say 7″ wide, in preparation for CNC router operations or whatever, is much harder to do without an 8″ jointer than it is to make rip cuts on a smaller table saw than a larger one. Benchtop planers can help with parallelism.

Basically, what I’m doing now is evaluating workshop priorities in order to maximize efficiency. I guess that will mean embracing less efficient tools or methods that will maximize convenience in other areas.

It feels strange. I worked so hard for so long to expand my capabilities, and now I’m looking to downgrade? If I have 1 hour to work on personal projects, I want that hour spent on getting things down, rather than maneuvering around parts, materials, machinery, etc.

It has also taken me a long time to understand what types of work I enjoy doing. If I can buy lumber that’s roughly surfaced to the thickness I need, that allows me to focus my time on the types of work that cannot be done for me – the type of work and projects I enjoy.

Sure, I would love to build large furniture, but I think I’ll have more fun making smaller contraptions. Smaller work is also easier to fit into my hectic schedule.

What do I want to do, and what will help me get there? When I first asked myself this question a long time ago, I needed more tools, and I acquired them in piecemeal. I couldn’t look at my workshop in a holistic sense, but now I can, or rather I should, and so I am.

Alexk

To replace a Sawstop, large bandsaw, large jointer etc. is probably 10 grand. Maybe worth getting a bigger shed to store that, kids stuff, gardening and plywoods?

Track saw, chop saw, small tablesaw, rikon 10” bandsaw, small helical jointer and planer should do.

I’m looking at it from my perspective. I have a tough time letting things go. If I could afford it, I’d love to pass things on to others knowing I could replace it if/when I needed to.

Stuart

I have a basic 14″ band saw, won’t part with it. It has a small footprint and once some lumber is turned into projects or donated, it’ll be easy to store until it’s rolled away from the wall for use.

The jointer would be pricey to replace today.

I wouldn’t buy the SawStop again – it was never going to be my “forever” saw. I haven’t fully utilized it, and upon examining all of my past, pending, and future project desires, I don’t think it’s vital.

I have a Dewalt benchtop planer (test sample), and while very good, it has a large footprint. I might be better served with a more compact helical-style benchtop planer that can be shelved.

With a benchtop saw or some rolling base saws, you lose the capability to cut dados. You also lose power and support space in front and behind the blade. Most portable table saws are not compatible with the same accessories, such as miter gauges.

The cabinet saw isn’t very large, but moving it into action or out of the way requires more Tetris-like efforts than other tools.

I knew it wouldn’t be a forever tool. I could replace my router table with a SawStop drop-in. But honestly, I think I could keep it if I remove the extension table and cut the rails down. This will impact cross cut support, but I feel it’s really best for cutting large plywood sheets which I’m not doing and won’t be doing.

If I cut the fence rails down and change my mind down the road, SawStop sells the full assembly, with front and rear rails and front tube, for $213.

Thus, there’s a chance I’ll be able to keep it for a while loner and shrink its footprint.

QR

I went with the Festool CSC SYS 50 after deliberating. Goal is to have all benches up against the garage walls when not in use, so a little different than yours. Then of course my first projects are larger, making cabinets, of course, and the tracksaw/small table saw definitely not as good there. I still have a fullsize bandsaw and router table, and probably will keep them, but everything else is benchtop. I might consider a larger planer/jointer machine in the future, like the Rikon, as the footprint is larger, but replaces two benchtop machines, and with a movable base might be ok for me.

I have one old HF rolling toolbox, but have found I don’t really use the drawers that effectively, and might end up replacing it with cabinetry at some point. Over time a lot of the loose tools I used to have, have been replaced with sets that have their own cases and lots of shallows drawers aren’t as needed.

I also went down the mft route, as having a folding table gives back space. If I had a single big table with the tablesaw, I don’t think the mft would get much use, though.

Dave

The Tekton Tool carts are made by Rousseau Metal I believe for them. Awesome tool cart, but definitely not cheap but made to last a lifetime. I’d like to see Tekton expands the line and adds some garage storage cabinets. They’ve done a nice job continually expanding the brands product portfolio overall.

isosceles

Stuart, what size sheds are you considering? It might be efficient to build the largest shed you can, and then either store rarely used tools in there, or just build it from the start with the idea that it’ll be a workshop.

Whatever footprint you choose, you can always build a couple of feet taller and give yourself some loft storage for stuff like scooters and lumber (as I’m sure you know).

I understand that going this direction might cut against the ethos of the reset as you’ve envisioned it, and that building a workshop can be a lot more complex than building a shed (electrical and so on). But I think it’s worth considering. Also, a workshop could potentially be expensed to some extent.

Stuart

Maybe a 10 x 16 garden shed – even that would require permitting and will need ground prep.

I had a subpanel put into the garage a few years ago, added outlets, insulated the walls, and added a mini split for heating and cooling.

A separate workshop would be extremely expensive. It might make more sense to lease a commercial space, and I’m very much averse to that.

My expansion has been rampant for nearly 20 years. It’s been time to slow down.

fred

I have a few sheds scattered about my property. They were added more for convenience (less lugging) than because of a need for extra footprint. But my basement shop has 2400 square feet of space – with good access via external entryway – and my 3-car garage with attic fills in for the rest. What I’ve learned about shed storage is that in the northeast – dampness can become the enemy of tool storage. My sheds are electrified but not airconditioned. My larger one – with potting benches and greenhouse space has powered ventilation – but it’s not always turned on. So, stuff rusts. Not so bad for hand garden tools – but I would not want to put my old heavy iron machinery into storage in any of them.

TomD

Sheds can be horrible unless you spend way too much building them – where a garage expansion would be a similar cost.

When I ran the numbers for me it was about ten years of storage space rental for an “outdoor equipment only” shed.

Yadda

Costco has several shed options including some in the range you are seeking. It is recommended to be a two man job to build them. All the parts are precut and the quality is pretty good. The package was delivered and bulk dropped in my driveway. I built/assembled my 8×15 with minimal assistance. My only gripe is the initial base parts you need are at the bottom of the pallet, requiring you to completely unload the pallet to start the project.

Yadda

I meant to add that cost wise their sheds are very affordable. The only supplies you need to add are shingles, caulk and paint.

Robert

Stuart, by the total amount of column inches you’ve devoted to this topic it’s obviously important to you, and that your readers follow the discussion. So it would help if you included in your articles rough floor plans of what you have and what you are intending. You probably have these as aids already for yourself.

Where you summarize: “ Storage and working surfaces are a priority right now, and this will continue to be true, more so than table saw or jointing capacity.”

Have you thought vertically? Give more working surface by tables that fold up against the walls when not in use, and more storage by bins/open top boxes that pull down from the ceiling (although that’s expensive).

In the movie Wrath of Khan, Spock critiqued Khan as thinking only 2 dimensionally. So Kirk maneuvered their ship vertically and came over the top of Khan.

Stuart

I’m not there yet. Right now I’m still sorting, culling, and prioritizing.

It’s a lot. I have a tote box with pneumatic tubing, another with 80/20 t-slot parts, another with non-marring hammers.

I have a bin with Arduino-compatible boards, some purchased for use and others for exploration purposes.

There’s a joke about how some people’s hobby is to collect hobbies. I’m kind of like that, but with skills and capabilities. I enjoy pushing my boundaries.

A lot of my storage was vertical, and I’ve backtracked on that. Ease of accessibility requires deliberate planning.

So what I’m doing now is reduction in anticipation of holistic planning. You can’t make a floor plan until you know what will remain past the immediate future.

I also have the pleasure and unique challenge of having to plan for unanticipated changes. For example, a new modular tool box tower arrived yesterday, and it’s got to sit somewhere while I evaluate it. I’m expecting another one in the near future.

As for things that pull down from the ceiling, that won’t be possible unless I add support pillars, and I’m not inclined to do that. I have high-up shelves in two spots, and they’re a pain to access. I also have some storage above garage-style wall cabinets, and that stuff is a pain to access too.

Bonnie

While I don’t practice full 5S, I did make a point when designing my current “dream” shop to include two sizes of “red tag” zone. One for small things like new hand tools that I haven’t decided where it goes, end of day cleanup, or stuff that isn’t ready to go back into deep storage, and a larger zone in front of one of the (disabled) garage doors for bulk project material and household stuff (christmas decorations in between being taken down and put into the attic, new water heater, etc) currently needed for projects. It’s been extremely helpful to corral clutter and reduce the mental load of figuring out where to put stuff that doesn’t have a home.

ChrisP

I have to use high shelving for storage – United Kingdom single garage: there wouldn’t be enough storage space if I didn’t use high shelves.

Access is straightforward – I have a tall stepladder that permanently lives leaning against the shelves and I use that for easy get to the top shelves, moving it to wherever I need access. It’s used like a library ladder

And when necessary, it also doubles as a tall stepladder 😉

Matt_T

“A mobile workbench the size of my SawStop table saw would be a dream.”

Put it on wheels and make a plywood top.

“I could remove the table saw’s extension table and chop off the extra fence rail sections, but that might be a detriment to the next user.”

If you need to take a torch to something to make it work for you go for it. Don’t worry about the “next guy”. If they don’t like your modifications they can go pay full retail for a new one. And since you donate stuff rather than sell it resale value is a non issue.

Stuart

It’s “permanence” that I am hesitant about. But as mentioned above I looked up the price of replacement rails, and they’re not that much. I’ll chop down the rails as soon as I can, maybe that’ll be enough.

Jim Felt

Stuart. I‘m getting a headache just following your otherwise swell progress. I simply can’t find the time in my present over committed life to even begin such (in my case) profoundly needed activity.

Best I can presently accomplish is reading about your path forward.

Darnitall.

Stuart

Baby steps are better than nothing. I’ve been making baby steps on this for years – this is the final stretch (or so I keep trying to convince myself).

Any action is better than waiting for ideal timing or circumstances.

TomD

Those rolling toolboxes are so beautiful and so rolly and they usually only roll twice; once off the delivery truck and once at the estate sale.

R Talma

My wanting/needing a shed ending up being a 600 sq foot garage, 20×30 with 10 ft high walls (size allowed by zoning without needing a hearing process). No regrets, everything is indoors. Tools, cars, toys, bikes, mower, snowblower, etc. If you need a permit, just build the biggest garage you can. You won’t regret the space. And I’d happily try out the Tekton toolbox when you are done with it.

Frank D

I used to have a 1 car garage ” shop ” for tools, projects & all kinds of storage. It was bound to be demolished, as a 100 year old horse & carriage shed/garage that was rotting away. But I carefully rescued & rebuilt it. I found it cramped and did my wood cutting outside.

A 10×16 shed, can be done, certainly for small projects; but would have to be the most organized ever, with everything on wheels.

I ” inherited ” a broken garden shed 8+ x 12 +, with broken floor system. Fixed the floor system. Fixed & raised the roof. Too tight inside to swing a cat. Instantly added two 6 foot side wings. One side has lumber and misc. storage. The other has a table saw, chop saw and planer. Each on a contractor base. The wood cutting side has tilt up end walls and side windows, allowing for full ventilation. Keeps the dust out of the shed.

While fun and do-able for small projects. It is frustrating, in three sections and too small. I have two circuits, tons of outlets and functionality; but it is not insulated, heated or cooled.

Anyway, I consider an oversized 1 car garage the minimum. Ideally with a carport for outside wood cutting. Probably better to have a two car garage with some attic storage and car port.

Of course space and budget have to allow for it.

Al-another-Al

I never thought of putting it in a drawer. I’ve been hiding my 12×18 granite on a makeshift plywood shelf on a 3-legged scroll saw stand. Geometry said it should be stable, but it’s a bear to move around.

Do you plan on using it from inside the drawer? I’ve only used mine as a flat surface for sandpaper.

MM

I like to build rolling stands for surface plates out of steel angle with heavy-duty casters underneath. I size them so they fit just underneath a workbench, the idea being you can roll them under the bench when you need it out of the way. I always make a close-fitted cover–basically a shallow box with no lid–out of nice plywood that can be placed over the granite when it is not in use. This keeps the granite clean and protected, plus it allows it to be used as a light duty work surface. The space underneath can be configured like you would a service cart and can be used to store measuring tools and other shop accessories like tooling, vises, lathe chucks, etc.

Stuart

No – that’s just temporary because the work top is currently the only proper work surface, and so I plopped the benchtop CNCs right on top.

Joseph P

I live in apartment in the city. I’m super lucky to be able to work in my side yard. It’s gotten me a bunch of side jobs. So there is a positive to it all as foot traffic can see my skills in person. But that means moving, unloading, setting up, running cords, and doing the reverse every time I want to work on a project. It has me seriously considering the layout of garage shop when we move next spring. To go from a storage locker shed I built to a proper garage will be so nice. The jack of all trades set up is one I’m also looking for.

More functionality and way less set up/break down. With this is idea that all toolboxes should have drawers. Why did we ever go to stacks? I can’t wait to abandon my stack. I just can’t justify buying a $750+ plastic toolbox to replace my stack atm. One day…

Rufus Jenkins

Stuart

Not sure if this will help but I put all my cordless tools into pack out and on the packout dollies. That is about the size I want to move around the shop and it’s easy. I probably have 10+ stacks. 6 of them I keep real close and the others I have put in deeper storage. The ones in more deep storage hold things like Rotary hammers and portabands. Then I took one wall and put lista cabinets that were not going to move. That was my hand tool storage and work bench area. I have one mechanic style cart with my most used hand tools. Then when I want to do a project whether it is on a car or on a table or on a machine I just bring my tool box swarm around the project. No idea how big your shop is so maybe it is not worth bringing the tools to the project but I find this helps me be super efficient. Essentially the work area is what I want to prioritize first then next I want to minimize my distance from commonly needed tools. I found building the packout stacks is a really easy way for me to get exactly what I want to the work with out having to push a heavy rolling box. They are super fast, extremely maneuverable and give me unlimited ability to expand 100-200 dollars at a time. It is also convenient if I need to go to a friends I just grab the right stack. Best of luck.