I bought a Precision Matthews PM728 benchtop mill over 2 years ago.

First, a minor annoyance. The oiler leaks. I was advised to remove the check valve, blow some air, and maybe a stuck ball will fix itself. I can’t tell where the leak is coming from, and so I haven’t done this yet. The chip tray is full of oil and a couple of bugs. This is still on my to-do list.

The bigger issue is that the spindle is defective. The R8 taper wasn’t machined correctly, and so it wasn’t holding onto collets properly.

Advertisement

I thought the problem was with my lack of experience, and I spent a ton of time trying to chase down excessive runout.

I finally looked online, found a known issue, contacted Precision Matthews, and they were great about confirming the issue and sending me a replacement spindle. That was 2 years ago.

Replacing the spindle sounded complex, and I avoided it for the longest time. I was still sour from all the time wasted trying to figure out the runout issue, and at some point I was waiting for a free weekend.

I made a point to finally replace the spindle today. First I’d swap the spindle, then test the machine, then plan and build a new stand for it, and finally convert it over for CNC use. This sounded like a plan. I was ready to get back to it!

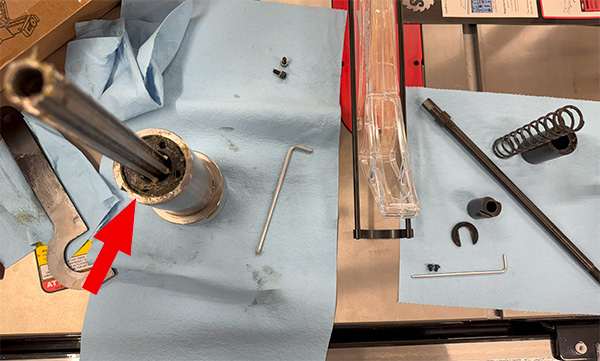

I got stuck. Removing the quill wasn’t too difficult, until it was time to disassemble it. This step was hard:

The spindle bearings are at either end, and a split nut at the top sets the tension and holds everything together. See Part 38 on page 20.

Advertisement

There are two set screws that when tightened, spread apart the slits in the nut and lock it in place. Loosen the two screws, and then use a straight punch or rod of some type with a mallet to tap the nut loose and then remove it.

Once I realized that the spindle nut was an internal retention nut of sorts, that’s when the fun began and I eventually used a pin punch in an a shallow hole with a wrench for leverage and a quill lock wrench holding the other end immobile. Looking online now, a pin spanner wrench would have helped.

“Tap it loose with a punch and a mallet.” If only that was the worst of it.

Next, with emphasis my own:

Once the nut is off, remove the screws holding the end cap on the tool end of the quill, and then tap the spindle out of that side of the quill. The top bearing will stay behind in the quill, which is fine, but you can remove it by tapping it out the other way with piece of dowel. The other bearing can then be slipped off of the spindle. It should not be such a tight fit that you need a press, as that inner race is held in tension by that nut you removed.

One bearing is loose, the spacer is loose, but the one that needs to move isn’t. I cannot slide them off the shaft. It is NOT a loose fit.

I tried a bunch of things to no avail. I tried to be gentle so as to avoid damaging the bearings.

I sent an email to Precision Matthews’ customer service, but I’m not sure what they can say. Hopefully they’ll have good news or good tips for me tomorrow.

It’s partly my fault for putting this off for 2 years. I bought the premium benchtop mill because it was supposed to be better. Having to work on it from the start was discouraging.

I went through so many disposable gloves handling things. If I can even get these bearings off, I might need to regrease them. PM provided guidance for that too:

The bearings can be inspected, but if you want to re-lube them, you’ll need to clean them out with solvent, and then use an actual spindle grease such as Kluber to grease them. They should not be filled more than about 30% or they will over heat. You can estimate that by filling one third of the circumference of the race all the way, and then spinning the bearing to distribute the grease around it.

I looked up the grease, and wow is it pricey. I hope I don’t need to go that route.

I HATE having to work on new machinery to get them to work. I shouldn’t have to sink hours into new machinery – isn’t that the point of buying new vs old? I also bought a Precision Matthews lathe, and that too required a bit of work and 1 replacement part. It still needs to be tuned and adjusted a bit.

As for reassembly, if I ever get to that part, I was told:

Assembly is the reverse, and the nut should only be tightened enough to remove any axial play in the spindle. Too much tension will also cause it to overheat, and too loose will make more noise. It’s all done by feel and sound here.

I’m not a “feel and sound” type of person, but hopefully it goes smoothly.

Hopefully they get back with some good advice. I’m not convinced – this was a limited problem they dealt with 2 years ago. Maybe the worst case scenario is that I will need to order replacement bearings and the spacer on my dime, even though this was all due to the factory defect.

Sorry, I needed to vent. I thought this would be a simple but time-consuming part replacement. Instead, it’s been time-consuming and I’m not done yet until I get past this part of disassembly without damaging anything. Hopefully nothing is damaged.

Maybe an extra-long bearing puller could do the trick, or a large hydraulic press. I have neither.

I put off replacing the defective spindle because I was sure it was going to be a giant pain. On the bright side, it looks like I was right.

I am 90% certain Precision Matthews will come through for me. But that doesn’t make me feel any better about the situation.

Would I buy the same machine again? Yes. My only regret is that I didn’t deal with all of this 2 years ago.

Amos Dudley

Sounds like a classic gumption trap!

Frank D.

Waw … that would frustrate and make me procrastinate too. But it is important to chase down such issues in the first month, pretty much.

One Christmas I purchased a Ridgid Caninet saw. Figuring it would help my woodworking and DIY. Assembly took time and effort. It was winter, did not use it. Then I found out that the saw motor and blade were out of square. Some disassembly required to make an adjustment … except nothing would budge. And I was afraid of braking something and injuring myself in the process.

All Ridgid offered was to take it to a repair center.

Okay, so disassembly, load up, drive hour +, drop off, return home, reassembly at the shop, testing, adjusting, drive to pick it up, see that it is fixed, disassemble for transport, get home, reassemble?

Eh no. I returned it to the store just in time under 90d. The assistent store manager would not take it, making me put my foot down and I had to explain the 90d satisfaction guarantee to him, that is literally on the box.

Anyhow. Hopefully you get it sorted without much extra frustration.

Brian J. Baumgartner

You mentioned a box and being able to drive it. Is it actually a cabinet saw, or is it the R4512 10″ table saw? (I have the latter, and am familiar with its problems.)

Adam Van

Did you try throwing the whole assembly into the freezer?

It’s great to be able to freeze the inner part and heat the outer part separately, but if you can get it all down to very cold, then try removing the outer as it warms up a bit faster than the inner part that might be enough.

Try to make sure you leave the part in the freezer oriented so it falls apart instead of loosening and slipping further together.

Stuart

I considered that, but not yet. I figured I’ll wait for PM’s recommendations.

Freezers can help with installations, but I haven’t heard much success stories about removal. I don’t have a torch; typically heat is required to expand the bearing.

MM

Your heat gun should do the trick.

Also, dry ice works a lot better than a normal freezer should you decide to go the thermal route. The bigger the delta between the two temps the better.

Aram

You can also buy “freezing spray” for this kind of thing. I used some to unstick a frozen lathe chuck component; freeze one part, leave the other room temp.

…I had considered using a resistive heating loop as well, but in my case it wasn’t necessary.

jeff robbins

Aerosol Dusters can work as the freeze spray in a pinch, just hit it for a longer time

jake

@jeff robbins – If you spray the duster with the can upside down doesn’t act like freeze spray?

jake

Oops! “doesn’t act” should read “doesn’t it act”.

I believe the duster should spray cold like freeze mist when the can is used upside down.

MM

@jake

Yes, it’s often the same stuff.

The lab I used to work in used to buy Shurfreeze brand cryogen spray from a medical supply company. It was quite expensive. After reading the MSDS we realized it was the same thing as the generic canned air duster from the local office supply store (tetrafluoroethane), just with a dip tube in the can so it sprays liquid instead of gas. Spraying canned air duster upside-down achieved the same thing at a fraction of the cost.

Reed Prince

I’ve used heat guns with success to remove capstan and tachometer rollers from 2″ tape machines.

MM

Dang, that sounds like a huge pain in the rear. Sorry to hear about the hassle, but that said it does not surprise me. Every “benchtop” machine tool I have encountered has been an exercise in frustration in one way or another. Yes, they are cheap–but you eat that cost several times over in time fooling around with the machine.

Stuart

All machines have Day 1 issues.

My Nova drill press had a defective gear rack, and the company seemed unknowledgeable about the product. Eventually they sent a gear rack. It wasn’t the same, but it worked.

Laguna band saw went *thunk thunk thunk*. After being on the phone with them for a while, they sent a replacement blade. That was the second saw, the first arrived nearly destroyed in transit.

SawStop table saw extension table was out of tolerance, and I had to stone an edge of the cast iron table where it wouldn’t align with the cast iron wing on one side.

PM lathe arrived with beat up splash guard and defective power switch.

Carbide 3D Nomad benchtop CNC has a slightly warped XY plate.

Carbide 3D Shapeoko CNC router had a defective gantry extrusion.

Buy a machine, expect some problems, whether benchtop or floor standing.

This machine was not “cheap.”

Troy H.

I think that part of the problem is that basically all of these hobby machines are still imports manufactured by a third party. Its not that you can’t get quality products out of Asia, but it is more difficult to qualify suppliers and maintain quality control compared to a product that is manufactured primarily in house by the company selling it (and it isn’t easy to do it when you’re doing the manufacturing yourself either.)

A brand can put time into qualifying manufacturers but its always going to be a moving target and its harder to catch a supplier or subcontractor change that could result in quality issues.

The problem for hobbyists is that it just isn’t generally feasible to pay what it costs for a machine that doesn’t have those kinds of problems and on top of that, some “pro” level machines are contract manufactured imports as well. So we get to spend some of our hobby time making the tools work instead of doing the creative stuff we really set out to do…

MM

None of those are what I would call true industrial or professional brands. They’re either hobbyist or rich-hobbyist. I would expect issues with all of them.

I know that those machines are not cheap. That’s why I am often so critical of them. The idea that you’re spending that kind of money and you still have fundamental problems like those you described is a bit ridiculous. But I’ve seen it time and time again. I saw the university I used to work at buy a lot of this kind of equipment and there were always problems, including with brands like Grizzly and Jet.

Stuart

The difficulty is that there’s nothing better in this size class.

The difference between consumer and industrial-grade calipers, indicators, etc, is often just quality, precision, reliability, and a higher price tag.

There is no better benchtop equipment. Precision Matthews is considered one of the better ones, compared to say Grizzly or Jet.

Very few companies make these types of machines.

Taig and Sherline are much smaller machines, and address the needs of a wide spectrum of consumer and industrial users. The same is true for most of PM’s machines and others like them.

There are smaller machines, the ubiquitous micro and mini mills and lathes.

The PM could be a tool room machine or similar. Commercial or industrial as in high duty cycle for production parts? No – I very much doubt it.

This is about closest to the largest and stoutest you can get without needing a rigging crew to move.

MM

I agree, machines in that size class are difficult to find. The reason is the “size class” is fundamentally flawed. A machine tool that small is just not any good for for doing serious work. The small size means the mass is low, and mass is one of the most important things about a machine tool. The small size also means the machines lack important features. Benchtop lathes usually lack power feed to the cross slide–and that’s assuming they even have feed to the apron which many don’t. Threading and feeds, when present, have few options and are often a hassle to select requiring the use of change gears. They rarely have rapids, and the chuck is usually direct threaded rather than camlock so it is much more of a hassle to swap. Small mills often have undesirable spindle tapers like R-8 and very rarely have a power drawbar. They tend not to have power feeds or rapids either. It can be tricky to mount a digital readout on small machines due to the limited space. No serious operator will put up with a machine that lacks those features. Because there are essentially no industrial customers for machines like this they aren’t made with the same sort of insistence on reliability and operator comfort that proper machines are. They are, as you said, hobby machines.

But Other machines, for example the Nova drill press, seem to be a specific marketing choice focusing more on fancy visual features like a touch-screen and a sleek housing, while completely ignoring much more useful features, like a geared low range, or power rapid to raise/lower the table.

Bonnie

That has *not* been my experience, and I’m glad. If I had to regularly do that much work on new tools I’d probably be an angry “Old Arn” grognard.

Most of my tools I have bought new just worked. I think my first larger resin printer (Saturn 2) has been the only real lemon, but all the others just worked. Only issue with my Sawstop was my own mistake misassembling part of the rolling stand. The saw itself was basically perfect. Same for my Jet Lathe, DeWalt planer… My Elegoo Neptune has had issues with clogging nozzles, but that’s a wear part anyways.

I don’t know if you just have terrible luck, or you see so many more machines come through your shop you see the problems more often.

Stuart

Bought a Wilton clamp-on vise, and the swivel feature never worked due to a large casting defect. I never got around to grinding it away.

A lot of tools work properly right out of the box. The ones that don’t have stood out.

Every miter saw I’ve ever tested has been square out of the box. The same with table saws except for the Bosch Reaxx.

I’ve seen a couple of cordless tool issues – one was improperly assembled and had its LED hanging out, and 2 of one brand’s impact wrenches in a row had defective power switches.

A Craftsman ratchet a long time ago skipped teeth, and they added a new production step to check for that.

I bought a large camera stand and the rotational bracket was defective.

I wen through 3 defective dehumidifiers where they all lost their refrigerant over time. The company swapped out the last for a smaller model, and it’s now leaking through the drain pan.

I dread freight deliveries because there’s usually some form of damage, defect, or other issue I have to deal with.

Bad luck? Maybe.

UberChemist

I’ve spent years looking. High quality small machine tools DON’T EXIST. It seems like a huge hole in the market. I want a mill small enough to be tucked away when not in use and works out of the box. Proxxon makes the closest I’ve found to this, but they’re too light duty for stainless steel.

MM

Emco has extremely nice small and benchtop machine tools. But anything you can just pick up and tuck away simply doesn’t have the mass to cut harder metal effectively. It’s not a question of precision or quality, it’s a physics problem: not enough mass to dampen vibration, and not enough room for the important features that serious customers would want. Even something like a Bridgeport mill, which I consider “pro-sumer” is wimpy in comparison to a more serious machine of similar footprint. Stuart mentioned various brands of small equipment above, like Taig and Sherline. These aren’t bad quality, the are in fact quite well made. It’s just that no matter how well made something is you need more mass if you want to cut harder metals effectively, and you need certain features if you expect to use the machine efficiently enough to make money with it. Today hardly any business will be making parts on manual machine tools, especially a small one. The only market left is hobbyists and small shops who would balk at a $20,000 desktop mill.

If you are serious about a high quality small lathe check out a Monarch 10EE. It sits on the floor but has a very small footprint. The milling machine is a bigger ask.

Daniel L

A MAPP gas torch on the inner raceway can expand the bearing’s diameter a bit. You’ll want to clamp the spindle and use thick leather gloves to slide the bearing off.

Only problem is that’s a delicate task. Too much heat and you can easily burn up the grease. Localized, high intensity heat is best for this task: you want the majority of the heat you apply to stay in the bearing and not conduct into the shaft, otherwise the shaft expands too and the bearing remains stuck. The goal is to expand the diameter just enough to get the bearing off with your hands.

Shoot, clamp it upside down and pad the spot where the bearing will drop. It might just fall off due to the force of gravity if you do it right. Though be careful it don’t hit you on its way down. Hothothot.

“Loose fit” when it comes to bearings is a relative term. Any kind of deformation or corrosion can easily make a “loose fit” bearing seem impossibly tight.

Mike

I would recommend freezer or dry ice first.

lower risk attempt than a torch and can work really well.

fred

We called one of our businesses a precision fabrication firm. And although we had sone truly heavy-duty machinery (leftover from a bygone era) we gained a local reputation for being able to disassemble most items without totally destroying them. We always tried induction heaters or selective freezing before a torch. Of course, sometimes EDM was needed – but at least that only was minimally destructive.

Hopefully PM will provide Stuart with some better ideas.

Daniel L

Honestly, the only reason I didn’t recommend that is because I’ve got no insight into how the grease would respond to below freezing temps. I know some don’t do well, but my knowledge in that realm is pretty limited. If it can handle it, though, no reason not to try.

Otherwise…shoot. Same thing could be done after freezing. The trick is keeping the heat as localized to the inner raceway as possible so that only the bearing expands, not the shaft.

An oxy-acetelyne torch with a fine tip would be *ideal* for carefully heating up the inner raceway until it came loose. But, yeah, I agree: it’s not the most risk-free proposition in the world.

Freezer is *probably* a good first step.

Matt_T

Guessing it’s the right hand bearing that’s stuck? If so tap it back down against the spacer then check for trash and burrs that might be stopping the bearing from slipping off.

Also the old spindle is trash? Cut it down so you can use a regular puller if you have to.

TomD

People have an idea that commercial/industrial equipment is “better” than those aimed at a home market – and sometimes it’s correct (Speed Queen, perhaps, or industrial shelving).

Other times it’s something like this that pretty obviously expects not to be installed in a garage but in a company that has a dedicated maintenance person who keeps them running. You can almost tell by just looking at it.

And reading the quotes from the manual confirms it.

Stuart

The quotes aren’t from the manual, it’s from a tech support email when I brought up the runout issue and they were sending out the replacement spindle.

Precision Matthews’ support has been good so far. Despite this, I would order from them again.

A lot of companies have similar or the same machines, but with superficial differences that make amount to big differences in user experiences.

PM’s documentation is pretty good, and their customer service people seem very familiar with the machines they sell.

I think that, due to the complexity of the replacement, it would have been a lot better if they sent me a replacement quill assembly, rather than just the spindle.

MM

I about spat my coffee across the room at the suggestion that this is an industrial machine.

Thank you, I needed a good laugh.

Stuart

No need to be rude.

No, I also wouldn’t consider it industrial grade, but it’s also not home center grade. I’d say it sits within demanding hobbyist and light demand pro/prosumer territory. You might find it in home workshops, but also tool rooms where there’s no need or space for a larger machine.

Yadda

I would love to own one of these milling machines, but no room or time. So I am experiencing ownership vicariously through you. Thanks for sharing. I’m sorry you are having these issues, but I do like reading your documented experiences. Hopefully you get things resolved and provide some interesting project updates soon.

Rcward

I would have returned that junk to where you got it

Ken H

Did you try putting the spindle in the freezer?

Brad J

I replace a lot of machine spindles. You need a hydraulic press and bearing pullers/separators to do it properly. Both are available at HF. How many r8 collets did you try in the bad spindle? Did you inspect it visually for debris/burs? You should have demanded a new machine, named dropped yourself and threatened to write an article. This is horrible press for them. I would never purchase a Mathews now and it was definitely a possibility.

Stuart

I didn’t do much with it as I was trying to chase down rundown before contacting them. The problem was that the spindle taper was contacting R8 collets at the front and nowhere else because the angle was off.

I removed the bearings with a lot of hammering – as they suggested – and I don’t think I damaged anything. I hammered the spindle a bit with the bearing braced on vise jaws and then moved separator jaws to contact the inner race.

Reseated the bearings on the new spindle by heating the bearings and cooling the shaft. The second bearing wasn’t budging, but I was able to use my small arbor press to get it in place.

Reassembled everything and tested it with no load. Runout seemed okay. I’ll make some test cuts over the weekend to check. I hope the bearings didn’t get mangled.

If anything seems damaged I’ll request or purchase a new spindle or quill assembly.

Name-drop and make demands? That goes against nearly 17 years of ToolGuyd policy and would be a disservice to everyone.

I didn’t hear back by 1pm so I gave them a call (in case I needed to pick up new tools over the weekend). We spoke a little, I sent a photo, they called back. They said to use a hammer, and that they had a spare bearing just in case. I called back, we talked about the bearings and how I’d notice damage if I spun the bearings by hand. They gave some input on how to install the bearings to the new spindle.

Precision Matthews provided great pre-purchase support, and their post-purchase support is just as good.

A new machine would have been excessive. A new quill or spindle assembly would have been nice instead of my having to go through such hassles to change out the spindle. Necessary? Maybe not. But, we’ll see how the test cuts go.

I would 100% buy more machines from Precision Matthews. But next time I’ll try to make sure I set aside a lot of time to immediately test and troubleshoot.

jeff robbins

This could be a Hail Mary play, but you might be able to use a hole saw to turn a plastic chainsaw wedge into a pickle fork that you could then hammer in to get the bearing to budge. The wedges are very hard and dense plastic, but way softer than metal, so that could do the job.

Ron

Hi Stewart. I strongly suggest that you visit the Hobby-Machinist.com site and register. Then, post your questions or frustrations in the Precision Matthews forum. The site is designed to be friendly period. If you catch flack from anybody, please contact the administrators.And they will take care of it. i’m pretty certain that someone at precision.Matthews also monitors the forum. As the situation was posted on the web, I can guarantee you.There will be other people that have had to deal with it and hang out so they can help others. If you find you do need to cool it, you can get dry ice from almost any supermarket. Ask at the service counter. Or CRC freeze works really well.

Stuart

They provided brute force suggestions that worked. I’ve been under the weather and waiting for a clear head day so I can make some test cuts and then measure for runout again.

I ended up using the head bed of my 3D printer, a heat gun, an hour of freezer time for the shaft, bearing separator jaws, a magnetic vise secured to my drill press, dead blow hammer, 1-ton arbor press, wood block, and a ton of cursing.

I’ve seen then respond on the forum. I don’t like that idea, as it leverages them to respond publicly.

I have not been 100% satisfied with the machine (yet/still), but 100% satisfied with how responsive Precision Matthews has been. They’ve been reasonable and attentive.

I was stressed out about the situation, and felt it necessary to vent while waiting. I was uncertain about what type of solution PM might present, but was sure they wouldn’t leave me on my own.

If it turns out that the bearings were damaged when removing them from the old spindle, that’d also be quite upsetting, but I’m sure PM will still provide satisfactory support.

Dan Boyd

I replaced the bearings on my 1969 Bridgeport mill and it was a similar process but so much easier. Tension on the bearings is set by a locknut that was removed with a spanner wrench. I made a jig to hold the spindle during removal and reassembly. The old bearings were clean and in great shape however I can now make the claim that my machine has all new bearings. Runout is undetectable with my .0001’s indicator !